Add to Cart

Reverse osmosis filtration system pharmaceutical waste water deep treatment2

Haiyuan water treatment team supply pharmaceutical waste water deep treatment solution for Belarus.

Please check below client met question and we solution for 23 m3 sewage infiltration 1m³ A project of concentrated water discharge

Here are the details of our discussion with customers:

According to the scheme, which was proposed by the designers - the final amount of salt concentrate after reverse osmosis should not be more than 5m3/week. From 23 m3 after ultrafiltration about 40 percent to reverse osmosis - 9.2 m3. And the concentrate will be about 1m3/day after RO - right?

Accord to your requirment we are calculate suspended solids:70mg/L,COD: 300 mgO2/l,BOD: 120 mgO2/l,When not reach COD<10 mgO2/l,BOD<5mgO2/l we will choose sand carbon(dosing device to remove COD and BOD).

And then use UF filtration to organic matter, bacteria, viruses, etc .

The remaining 40% of the concentrated water will be returned to the cesspit where it will be treated and then RO will be deal with it.

We agree, with the characteristics you have chosen to calculate the cleaning system. In view of the lack of opportunities to conduct tests, it may be worth reinsuring and slightly overestimate the figures.

However, we are not quite clear, how will now look the scheme of purification: after flotation sand and carbon filter, ultrafiltration, reverse osmosis?

------ after flotation sand and carbon filter,ultrafiltration, reverse osmosis.

Is it possible to do only filters (change the carbon load and flushing more often) and reverse osmosis?

----No ultrafiltration. then RO membrane will be quickly blocking.

According to the scheme, which was proposed by the designers - the final amount of salt concentrate after reverse osmosis should not be more than 5m3/week. From 23 m3 after ultrafiltration about 40 percent to reverse osmosis - 9.2 m3. And the concentrate will be about 1m3/day after RO - right?

-----23m3*90%(UF Permeated water)=20m3*40%=8.28m3(RO concentreated water).

8m3 of concentrate after RO is still quite a lot, so please advise - maybe there is a possibility to put the second stage of reverse osmosis with other membranes to reduce the amount of concentrate?

Please confirm the drawing with your engineer to confirm the solution your custome

ultrafiltration is not provided in the project, so they are not ready to install it. However, it is possible to deviate from the project in the direction of increasing the volume of concentrated water.

Is it possible to use columns of higher capacity to compensate for the amount of suspended solids, as well as to install a fine filter (on the pipeline) to contain the slipped carbon? Further two stages of reverse osmosis?

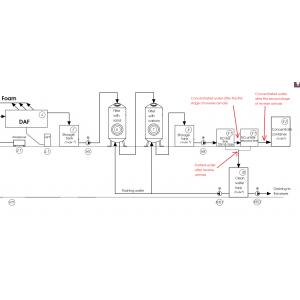

I also attach a scheme of purification by the project :Our technologist today studied in detail the scheme of reverse osmosis at 23m3/day, paid attention to the capacity of the equipment. The equipment will work 12 hours a day - will the capacity of the equipment that you have given for this mode of operation be enough? That is, the actual productivity will be about 2-2.5m3 / hr 12 hours a day, not 1m3 / hr 24 hours. Or you need more productive equipment?

There are have to enough raw untreated water feed sand carbon and RO. And passed many times we can get the finall conecentreated water. If not enouh feed water to ro how can pass 3 times treatment get the 1m3/D concentreated water.

The water supply is 5.12m3/hr(25m3/D) After three times of concentration, it can reach 1m3/D.

The system does not need to run continuously for 10 hours, it may only run for 4 to 5 hours to process 23m3.

When raw untreated water is too less water. The system can automatically stop.

Only with such a water inflow can the final 1m3 concentrated water be obtained.

Raw untreated tanks are filled with low float balls. It will automatically stop working if there is no water.

Process flow:

Raw water tank - booster pump - multi-media filter - activated carbon filter - precision filter - sand and carbon water tank - scale inhibitor - primary high pressure pump - primary RO - product water tank (primary concentrated water tank)

Primary concentrated water tank - secondary pressurized magnetic - precision filter 5/1 µ - secondary high-pressure pump - secondary RO - product water tank (secondary concentrated water tank)

Second-stage concentrated water tank - third-stage pressurized magnetic - precision filter 5/1 µ - third-stage high-pressure pump - third-stage RO - product water tank (third-stage concentrated water tank)

FAQ:

Install and commissioning questions.

1st. All the plants will be commissioning and running well for 3 days then delivery. Installation video, photos, operating manual will send to client with the plants.

2nd. Clinet can come to factory for training how to installation and maintenance.

3rd. Some main parts will be guaranty two years.

4th. Engineer can go to overseas for installation and commissioning.

How to control quality?

1. Our company has passed ISO9001:2008 and SGS certification and all manufacture processes are conducted by the standard strictly.

2. All products adopt RO system simulation software design.

3. All auxiliary parts adopt international and Chinese famous brand products.

4. Before delivery time ,all complete sets will test run for 3 days continuously After quality inspection, they can be transferred to the customers

5. We have obtained many patents certification from government.

Send your Inquiry Details in the Below, Click "Send" Now!

ave obtained many patents certification from government.

More inquiries related to Water treatment please contact:

Connect:Eva

Mob& Wechat& WhatsApp: (+86)13532836525

Email: sales007@water-sy.com